Project Description

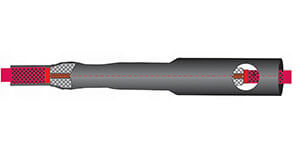

These joints are suitable to be installed on various types of single-stranded armored cables and connect two armored cables with the same size. Given the lack of metal case in this joint, it is designed in a way that an electric connection would be established at two directions between the armor of the cables.

These joints are mostly used in electrical substations, cities or factories which do not need protection against mechanical pressures applied from the environment, and considering lack of using armor case, the diameter of the joint is approximately the same as that of the cable and is quite suitable for use on a cable tray.

- Insulating tubing

- Stress control tubing

- Yellow tape

- Semi-conductor tape

- Insulating tape

- Copper mesh

- Two-layer tubing (red / black)

- Medium voltage ferrule

- Earth ferrule

- Installation manual

- Taped jacketing tubing

- Earth kit (if the earth is tape shield)Armor kit

- Room temperature ranging from -40 to +105 °C

- Cross-linked polymer insulation

- Flame retardant

- Easy installation

- In accordance with DIN VDE 0278, CENELEC HD 629.1S1, IEC60502-4 Standard

- With UV protection layer

- With unlimited lifetime / energized as soon as it is installed on the cable

- With integrated jacketing tape for the sealing of the whole joint

- Smaller volume in comparison with joints with armor case

To order for a cable with specific cross section and conductor type, you can act as follows at the time selecting the code.

For instance:

Single core joint with a voltage of 24kv and 185 mm2 cross section and PHJUV – 1124 – 185 AL aluminum ferrule

| X = cable cross-section (mm2) Y= (CU/ AL /BI) Type of ferrule |

| Cable cross-section (mm2) | Code | Uo (kV) |

Un (kV) |

Um (kV) |

| 6 – 1200 | HJUV – 1103 – XY | 1.9 | 3 | 3.3 |

| 6 – 1200 | HJUV – 1107 – XY | 3.3 | 6 | 7.2 |

| 10 – 1200 | HJUV – 1112 – XY | 6 | 10 | 12 |

| 10 – 1200 | HJUV – 1117 – XY | 8 | 15 | 17.5 |

| 10 – 1200 | HJUV – 1124 – XY | 12 | 20 | 24 |

| 10 – 1200 | HJUV – 1136 – XY | 19 | 33 | 36 |